It would be very painful for me to see someone pay a hefty sum of money to a technician for cleaning generator’s carburetor knowing you could do it yourself at home.

Speaking of generators, have you ever been curious about other items and objects that begin with the letter ‘G’?

If you want to save your money, and learn how to clean a generator carburetor without removing it, then make sure to read this guide thoroughly!

Table could not be displayed.The unfortunate reality is that it’s mostly impossible to know how to clean a generator carburetor without removing it. In order to clean the carburetor of your generator properly, you’ll have to do some disassembly and removal research so that you can access the device properly.

To avoid paying hefty fee to a generator technician for cleaning the carburetor of your generator, read this guide thoroughly and follow the instructions.

Why Do You Need to Clean the Generator Carburetor?

The carburetor is where the gasoline and the air to be burned cross, and because most engines are not always in use, it is also where the fuel starts to detach and obstruct the pipes.

Ethanol-based fuels are primarily to blame, because ethanol evaporates and absorbs moisture inside the channels that allow the carburetor to choke.

Such clogs may trigger a range of problems, from sputtering and backfiring, to not making the generator run.

Why Can’t You Remove the Generator Carburetor?

For several factors, having the carburetor mounted would make it almost impossible to clean the carburetor properly unless the generator has a special configuration that requires it to be placed.

Even in that situation, it is still advised to clear it, as you will not be able to drain the excess fuel or clean the clogged canals properly.

What You Need to Clean a Generator Carburetor

Upon starting the process, you will need to clear enough space to keep all your parts and equipment secure, and to clean up the spilled oil quickly.

Some equipment you’ll need:

- Flathead Screwdriver

- Smaller Flathead Screwdriver

- A collection of pliers

- 8mm Socket and Ratchet

- 2 Fuel Line Clamps

- Carburetor Cleaner

- Drain Pan

- Rag

- Safety Goggles

How to clean a Generator Carburetor without removing it

Once you start cleaning, make sure that the fuel valve is off to prevent leakage and that the unit is off.

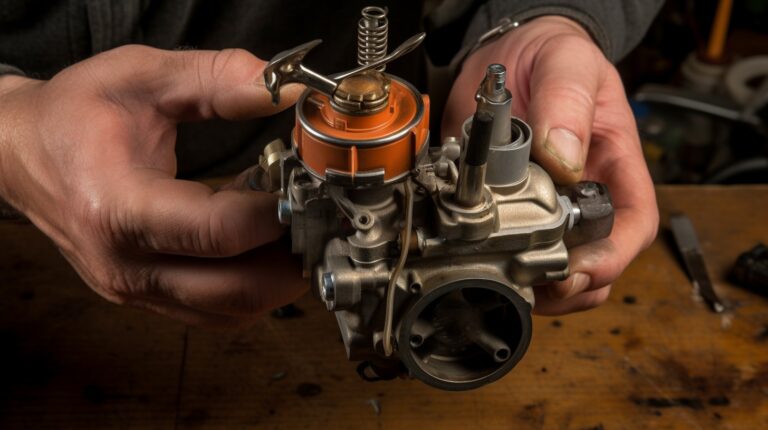

Getting to the Carburetor

On most generators you’ll note a side panel with a lock on it. Clear the side panel to show the internal components and locate the carburetor.

First, disconnect the air filter, and cut the thin, black hose that attaches the air cleaner to the crankcase. Use the screwdriver to detach the screw at the front of the pipe, and then the plug and the ratchet to extract the 8 mm screws that retain the filter frame.

With the air filter off, you now have access to the carburetor of the engine. Use your pliers to cut the fuel line from the fuel pump to the carburetor. Repair the fuel line.

Upon cutting the little clamps and replacing the carburetor, you’re more likely to notice the leaked fuel that you should wipe away with the rag right away. Then empty the fuel bowl of the carburetor by placing it over the drain pan and using a small flat-head screwdriver.

There should be a tiny flathead screw at the base of the carburetor, which you can remove to complete the drainage. Alternatively, on some versions, you can see a hose that removes the fuel bowl from the bottom of the whole unit.

Upon loosening the screw and extracting the fuel bowl as much as possible, you can find a white cover on the top that governs the eco-control. Remove the cover and the wires to completely remove the generator from the carburetor.

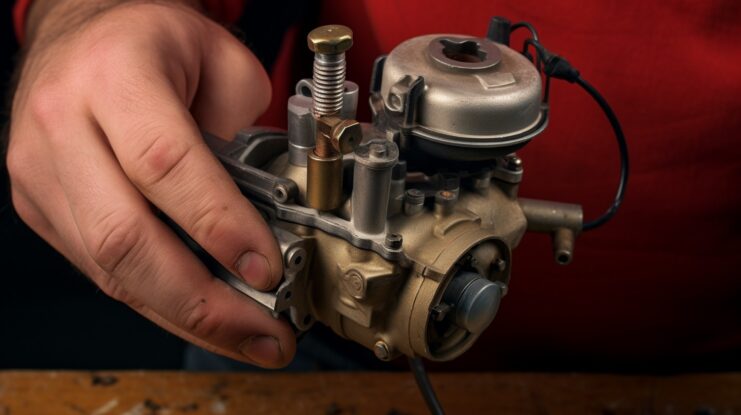

Cleaning the Carburetor

With the carburetor separated from its fuel lines, cut the gasket and check it for defects, or tears of any kind. If it is broken, consider replacing it.

Now detach the 10 mm bolt from the bottom of the float tank when placing the carburettor over the drain pipe. This is to trap some gasoline that might have been trapped in a bowl that will spill out once the bowl has been drained.

Inspect the now-removed bowl for any cloggings or dirt that may be at the bottom of the bowl and make sure it is well washed and polished as appropriate.

Returning to the carburetor, taking out the float and the float screw. The float controls the flow of fuel into the system and either makes more or stops fuel from moving into the carburetor. Inspect for any losses.

You will encounter another gasket that ties the float bowl to your carburetor; extract this gasket and fix it as it will stretch any time you remove the float bowl.

When removed, check the main jet and clean it thoroughly, as this is where the key clogging can occur. Make sure you also get the small holes on the bottom.

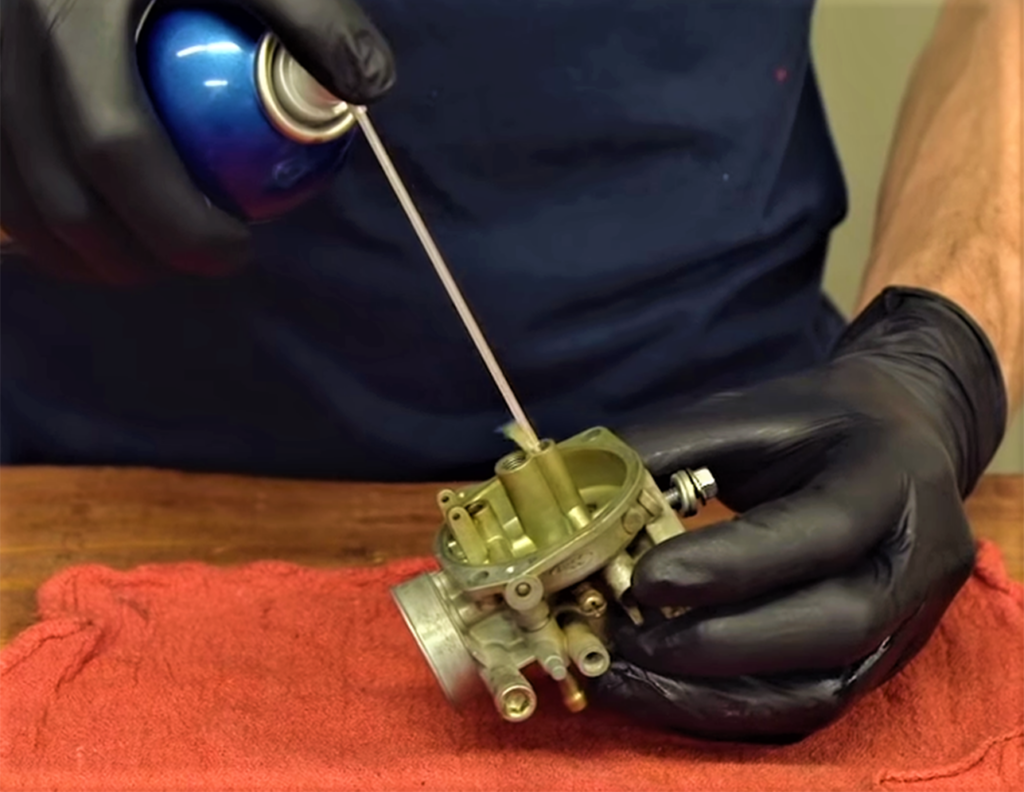

Add the straw to the carburetor cleaner and put your safety glasses on your nose, spray both ends of the main jet and then again with compressed air.

Do this in the float tank, too, and with the carburetor, move the straw to the spot where the inlet needle goes and the fuel drops in to flush out the pump.

Spray through the entire system, where the primary jet was replaced and the air orifices in the front and back of the carburetor were eliminated. Make sure to follow up with compressed air after each spray of the carburetor cleaner to avoid any residue and leftover cloggs.

Reassembling the Carburetor

After cleaning the carburetor, you can start by reversing the disassembly process. Reinstall the jet tube to slide the main jet back in.

Insert the small flathead screw you used to release the jet and tighten it again, but not tight enough to over-torque the carburetor and destroy it.

Connect the new float bowl to the gasket and put the float back on the carburetor, mount the float plate. Reinstall the float tank, make sure you have a drain valve facing the front of the carburetor.

Place the float bowl where it was initially, secure it with a 10 mm wrench, be cautious not to over-tighten it, not to ruin the carburetor.

Replace the gasket between the end of the valve and the carburetor. Next attach the eco-control cables.

Replace the first gaskets that you extracted from between the air philtre and the carburetor, reconnect the fuel lines with the clamps, detach the hose and put it in, then reinstall the air philtre and the fuel lines.

Switch on the fuel valve to test for possible leakage and remove the side panel until pleased.

FAQs

Why is it essential to clean the generator carburetor?

The carburetor is where gasoline and air mix for combustion. Over time, especially with ethanol-based fuels, residues can build up, leading to clogs. These clogs can cause various issues, from sputtering to the generator not running at all.

Can I clean the carburetor without any disassembly?

While the guide provides a method to clean the carburetor without fully removing it, some disassembly is still required to access and clean it properly. It’s essential to follow the steps carefully to ensure thorough cleaning.

What are the primary tools I’ll need for this cleaning process?

Some of the main tools include a flathead screwdriver, pliers, an 8mm socket and ratchet, fuel line clamps, carburetor cleaner, a drain pan, and safety goggles.

Is it possible to clean it without any specialized tools?

While it’s possible to clean the carburetor with basic tools, having specialized tools like carburetor cleaner and fuel line clamps can make the process more efficient and safe.

Why is it not recommended to remove the generator entirely?

Removing the carburetor entirely can be a complex process and might require recalibration when reassembling. Cleaning it without full removal ensures that you can maintain its settings while still giving it a thorough clean.

How often should I clean it?

The frequency of cleaning depends on your generator’s usage and the type of fuel you use. However, if you notice performance issues or if the generator has been sitting idle for an extended period, it might be time for a cleaning. Regular maintenance checks can help determine cleaning needs.

Conclusion

Understanding the intricacies of your generator’s carburetor isn’t just about saving money—it’s about empowerment. By taking the time to delve into this guide, you’ve equipped yourself with the knowledge to maintain an essential piece of equipment.

Remember, a well-maintained carburetor ensures that your generator runs efficiently, providing you with reliable power when you need it most. So, the next time your generator acts up, you’ll know exactly what to do. Here’s to self-reliance, smooth-running generators, and the satisfaction of a job well done!

Related Posts:

- Tecno Spark Go 2024: The Ultimate Smartphone Revolution

- Top 10 Best Robot Vacuum Cleaners 2024 - Clean Your…

- How to Power On, Power Off, and Reboot Galaxy S21,…

- How to Project Laptop Screen to Wall Without…

- How to Take Screenshot on Galaxy S7 and Galaxy S7…

- How To Charge A Bluetooth Speaker Without A Charger…